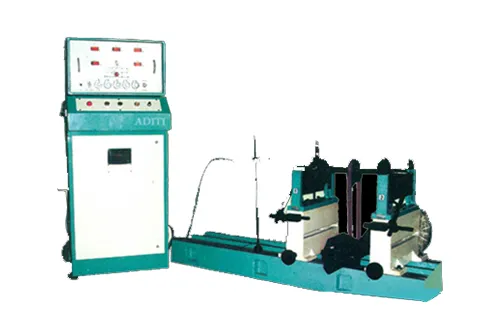

ADITI ENGINEERS'S Horizontal Belt Driven Balancing Machines provide accurate readings, time after time. Sturdy design combines the precision of piezoelectric transducers in a reliable, hard-bearing support system on a solid-steel base. Belt Driven Horizontal Balancing Machines are ideal for Rotors like armatures, textile or machine spindles, shafts, turbines, printing / paper machine rollers, submersible pumps rotor and other applications requiring high-precision balancing.

| MODEL | UNIT | AHP-10 | AHP-50 | AHP-100 | AHP-300 | AHP-1000 | AHP-2000 | AHP-3000 |

|---|---|---|---|---|---|---|---|---|

| WEIGHT RANGE | ¢ Kg. | 0.2 to 10 | 1to 50 | 3 to 100 | 3 to 300 | 10 to1000 | 20 to 2000 | 30 to 3000 |

| MAX. DIAMETER | ¢mm. | 200 | 400 | 800 | 800 | 1200 | 1200 | 1500 |

| JOURNAL DIA. | mm. | 5 to 30 | 5 to 50 | 5 to 75 | 5 to 125 | 15 to 150 | 15 to 150 | 20 to 220 |

| MIN. DISTANCE BET. ROLLER SUPPORT | mm. | 100 | 100 | 150 | 200 | 300 | 300 | 400 |

| MAX. DISTANCE BET. ROLLER SUPPORT | mm. | 400 | 900 | 2300 | 2300 | 2700 | 2700 | 2600 |

| BALANCING SPEED | RPM | 700 to 1500 | 700 to 1000 | 500 to 1000 | 400 to 800 | 300 to 600 | 300 to 600 | 250 to 500 |

| DRIVE | HP | 0.5 | 0.75 | 1.5 | 3 | 10 | 12 | 15 |

| MIN. UNBALANCE READ | Gms. | 0.01 | 0.1 | 0.1 | 0.1 | 0.1 | 1 | 1 |

| MAX. UNBALANCE READ | Gms. | 500 | 500 | 1000 | 1000 | 2000 | 2000 | 2000 |

| MIN. UNBALANCE | g.mm. | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 25 | 25 |

| MIN. ACHIEVABLE UNBALANCE (FOR MAX. WT. OF THE ROTOR) | ~OR g,mm/Kg | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

Note.:

• The pedestals are designed to take 25% occasional overload.

• The above machine operates on mains of MaV, 3Ph.

• The dimensions given above are approximate.

ADITI ENGINEERS'S Horizontal Balancing Machines provide accurate readings, time after time. Sturdy design combines the precision of piezoelectric transducers in a reliable, hard-bearing support system on a solid-steel base. These Horizontal Balancing Machines meet a wide rang of requirements.Depending on the rotor features and your process needs, these balancing machines may be used for universal applications inccluding armatures, Precision spindles shafts pump impellers, blowers, fan, turbines, rollers, and ather applications requiring high-precision balancing.

| MODEL | UNIT | AHD 50 | AHD 100 | AHD 300 | AHD 500 | AHD 2000 | AHD 3000 | AHD 5000 | AHD 1000 |

|---|---|---|---|---|---|---|---|---|---|

| WEIGHT RANGE | Kg. | 1 to 50 | 3 to 100 | 3 to 100 | 3 to 300 | 10 to 1000 | 20 to 2000 | 30 to 3000 | 100-10000 |

| MAX. DIAMETER | mm. | 500 | 400 | 800 | 800 | 1200 | 1200 | 1500 | 2500 |

| JOURNAL DIA. | mm. | 5 to 50 | 5 to 50 | 5 to75 | 5 to 125 | 15 to 150 | 15 to 150 | 20 to 220 | 25 to 300 |

| MIN. DISTANCE BET. ROLLER SUPPORT | mm. | 50 | 100 | 150 | 200 | 300 | 300 | 400 | 500 |

| MAX. DISTANCE BET. ROLLER SUPPORT | mm. | 1400 | 900 | 2300 | 2300 | 2700 | 2700 | 2600 | 3300 |

| BALANCING SPEED | RPM | 700 | 700 to 1000 | 500 to 1000 | 400 to 800 | 300 to 600 | 300 to 600 | 250 to 500 | 150 to 300 |

| DRIVE | HP | 0.75 | 0.75 | 1.5 | 3 | 10 | 12 | 15 | 40 |

| MIN. UNBALANCE READ | Gms. | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 1 | 1 | 10 |

| MAX. UNBALANCE READ | Gms. | 500 | 500 | 1000 | 1000 | 2000 | 2000 | 2000 | 20000 |

| MIN. UNBALANCE | g.mm. | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 25 | 25 | 25 |

| MIN. ACHIEVABLE UNBALANCE (FOR MAX. WT. OF THE ROTOR) | ~OR g,mm/Kg | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

Note.:

• The pedestals are designed to take 25% occasional overload.

• The above machine operates on mains of 3ph. 440v / 50Hz or 380v / 60Hz.

• The dimensions given a bove are approximate.